There’s an important role in any medical visit that patients rarely see yet rely on more than they’ll ever know.

A sterile processing technician is tasked with keeping instruments, surfaces, skin, and any other object in a medical office or operating room safe from viruses or bacteria and preventing cross-contamination.

This goes beyond just using soap and water to give the appearance of clean.

It’s a delicate balance of protecting gear while sterilizing with growing technology.

A sterile processing technician job is a great way to make a difference in the medical field without extensive education.

Job Description: What Does a Sterile Processing Technician Do?

Perhaps the most resonating sterile tool the average person sees is the blue water called Barbicide, found in the local salon.

The shears or combs are soaked in the product to disinfect.

On a much larger scale, sterile processing technicians do the same thing through focused training.

The primary responsibility of a sterile processing technician involves meticulously cleaning, decontaminating, inspecting, packaging, and sterilizing equipment used in the medical setting.

From the moment a medical tool is used in a procedure until it goes to the next patient, the technicians ensure safety and sterility in compliance with hospital and medical guidelines.

Duties

- Clean, decontaminate, and disinfect surgical instruments and medical equipment.

- Sort and disassemble instruments as needed for thorough cleaning.

- Operate sterilization equipment.

- Inspect instruments for cleanliness, damage, or defects.

- Reassemble, package, and label sterilized instruments for future use.

- Maintain records of sterilization processes, equipment maintenance, and inventory.

- Monitor and maintain sterile storage areas.

- Track inventory levels and restock sterilization supplies and equipment as needed.

- Follow strict infection control and safety protocols to prevent contamination.

- Stay updated on best practices, safety standards, and new sterilization techniques through ongoing training and education.

Salary: How Much Does It Pay?

The average annual salary for a sterile processing technician is $40,390 per year or about $19.41 per hour.

The highest end of salary expectations would be around $50,000, with the low end around $32,175.

At the entry level, the positions pay an average of $39,184, with a 6% increase to $41,608 expected after two to four years of experience.

Those looking to advance to sterile processing manager in the future could reach a salary of around $96,000.

Average National Salary: $40,390

Salary Information by State

| State | Employed | Avg. Annual Salary | Avg. Hourly Pay | Top 10% Annual Salary | Bottom 10% Annual Salary |

|---|---|---|---|---|---|

| Alabama | 890 | $36,040 | $17.33 | $47,080 | $26,980 |

| Alaska | 200 | $54,070 | $26.00 | $77,730 | $39,140 |

| Arizona | 2,180 | $45,530 | $21.89 | $58,370 | $34,210 |

| Arkansas | 410 | $37,860 | $18.20 | $44,190 | $33,000 |

| California | 8,630 | $64,820 | $31.16 | $87,960 | $40,510 |

| Connecticut | 910 | $48,790 | $23.46 | $61,590 | $37,700 |

| Delaware | 250 | $53,090 | $25.52 | $61,640 | $45,550 |

| District of Columbia | 220 | $58,410 | $28.08 | $75,570 | $37,870 |

| Florida | 4,150 | $44,290 | $21.29 | $58,450 | $34,540 |

| Georgia | 1,890 | $47,310 | $22.75 | $63,250 | $34,650 |

| Hawaii | 330 | $50,590 | $24.32 | $59,360 | $41,600 |

| Idaho | 420 | $48,000 | $23.08 | $70,850 | $30,310 |

| Illinois | 2,860 | $50,250 | $24.16 | $69,380 | $37,970 |

| Indiana | 1,500 | $43,110 | $20.73 | $57,240 | $31,230 |

| Iowa | 600 | $42,550 | $20.46 | $53,890 | $36,200 |

| Kansas | 660 | $43,630 | $20.98 | $56,970 | $32,570 |

| Kentucky | 1,010 | $44,130 | $21.22 | $58,720 | $34,320 |

| Louisiana | 680 | $36,200 | $17.41 | $48,780 | $22,740 |

| Maine | 480 | $46,230 | $22.23 | $56,850 | $38,170 |

| Maryland | 1,240 | $49,330 | $23.72 | $62,650 | $32,070 |

| Massachusetts | 1,670 | $55,060 | $26.47 | $75,750 | $39,500 |

| Michigan | 2,550 | $45,330 | $21.79 | $54,410 | $37,620 |

| Minnesota | 1,260 | $49,900 | $23.99 | $58,380 | $39,200 |

| Mississippi | 290 | $35,610 | $17.12 | $46,320 | $27,240 |

| Missouri | 1,610 | $44,210 | $21.26 | $55,040 | $34,550 |

| Montana | 300 | $43,100 | $20.72 | $54,310 | $32,750 |

| Nebraska | 520 | $42,880 | $20.61 | $55,810 | $36,660 |

| Nevada | 540 | $45,680 | $21.96 | $58,700 | $38,370 |

| New Hampshire | 450 | $49,290 | $23.70 | $59,160 | $38,950 |

| New Jersey | 2,230 | $52,640 | $25.31 | $66,310 | $38,370 |

| New Mexico | 220 | $42,940 | $20.64 | $54,570 | $31,190 |

| New York | 5,340 | $52,860 | $25.41 | $67,300 | $38,400 |

| North Carolina | 2,740 | $43,750 | $21.03 | $54,770 | $33,350 |

| North Dakota | 340 | $48,220 | $23.18 | $59,190 | $36,360 |

| Ohio | 3,210 | $43,460 | $20.89 | $55,240 | $33,900 |

| Oklahoma | 720 | $42,060 | $20.22 | $52,680 | $31,280 |

| Oregon | 1,690 | $50,550 | $24.30 | $63,160 | $35,910 |

| Pennsylvania | 2,730 | $45,200 | $21.73 | $57,710 | $36,090 |

| Rhode Island | 200 | $52,300 | $25.14 | $67,680 | $41,120 |

| South Carolina | 1,250 | $42,510 | $20.44 | $53,780 | $30,540 |

| South Dakota | 380 | $40,400 | $19.42 | $48,780 | $30,520 |

| Tennessee | 1,510 | $43,950 | $21.13 | $58,270 | $31,480 |

| Texas | 3,790 | $46,100 | $22.16 | $61,150 | $34,270 |

| Utah | 670 | $46,170 | $22.20 | $61,350 | $37,820 |

| Vermont | 120 | $48,010 | $23.08 | $64,050 | $38,420 |

| Virginia | 2,040 | $46,690 | $22.45 | $60,150 | $37,080 |

| Washington | 1,680 | $54,210 | $26.06 | $78,260 | $34,750 |

| West Virginia | 480 | $42,540 | $20.45 | $52,160 | $31,200 |

| Wisconsin | 1,250 | $45,800 | $22.02 | $55,890 | $36,880 |

| Wyoming | 80 | $47,020 | $22.61 | $58,650 | $35,810 |

| Guam | 40 | $42,540 | $20.45 | $79,090 | $23,920 |

| Puerto Rico | 130 | $26,650 | $12.81 | $33,210 | $19,900 |

Annual Average Salary: Top 10 States

The top earning state in the field is California, where the average salary is $64,820.

These are the top 10 earning states in the field:

* Employment conditions in your area may vary.

How to Become a Sterile Processing Technician: Step-by-Step

Step 1 Understand the Role

Before diving into the educational requirements, it’s important to fully understand what a sterile processing technician does.

They are responsible for cleaning, sterilizing, and preparing medical instruments and equipment used in healthcare settings.

This role is crucial for patient safety and infection control, but you may encounter biological materials, including tissue and fluids, on surgical instruments and equipment.

Be sure you have the stomach for such things.

It’s also important to understand the physical demands of the job, with an eye test to see how well you can view small print or measurement markers at close range or keep a steady hand while working with chemicals and sharp tools.

Step 2 Earn a High School Diploma or GED

To start on this career path, you will need a high school diploma or GED.

This is the minimum educational requirement for most entry-level positions.

Having basic skills in STEM education, science, technology, engineering, and mathematics goes a long way to building a foundation of education in this future role.

The more advanced the level of classes you excel in, the easier the next phase of education will be.

Step 3 Complete a Sterile Processing Technician Program

While not always mandatory, completing a formal sterile processing technician program significantly enhances your job prospects.

Community colleges, vocational schools, or online education providers typically offer these programs.

They usually take a few months to complete and cover key topics such as:

- Microbiology and infection control

- Medical terminology

- Instrumentation

- Sterilization procedures and equipment

- Inventory management and record-keeping

- Programs often include both classroom instruction and hands-on training in a clinical setting, which allows you to gain practical experience in sterilization techniques and equipment handling.

Step 4 Obtain Certification

Although certification is not required in every state, it is highly recommended as it demonstrates your competence and commitment to the field.

The most recognized certificate for sterile processing technicians is the Certified Registered Central Service Technician (CRCST) offered by the Healthcare Sterile Processing Association (HSPA).

To become certified, you will need to:

- Complete a minimum of 400 hours of hands-on experience in a sterile processing department.

- Pass the CRCST exam, which tests your knowledge of sterilization, decontamination, and the role’s overall responsibilities.

- Another certification option is the Certified Sterile Processing and Distribution Technician (CSPDT) from the Certification Board for Sterile Processing and Distribution (CBSPD). Both certifications require ongoing education to maintain your credentials.

Step 5 Gain Hands-On Experience

Experience is key in this field, and many employers prefer candidates who have hands-on experience in a healthcare setting.

After completing your formal education, consider seeking internships, externships, or entry-level positions in hospitals, outpatient clinics, or surgical centers.

These opportunities will help you apply what you’ve learned, hone your skills, and become familiar with the fast-paced environment of a healthcare facility.

It’s important to know that your skill set matches the mental and emotional on-demand requirements of a surgical center, hospital, or doctor’s office.

Step 6 Apply for Jobs

Once you have completed your training and obtained certification, you can start applying for jobs as a sterile processing technician.

When preparing your resume, highlight your certification, relevant coursework, and any hands-on experience you’ve gained.

References from surgeons or doctors will add to your accolades and potentially allow you to stand out in a crowd of applicants.

Tailor your cover letter to emphasize your attention to detail, commitment to patient safety, and ability to work under pressure.

Step 7 Continue Your Education and Stay Certified

The evolution of equipment sterilization goes back as far as 3000 BC, and there’s always a new way to tackle tasks.

This could include more cost-efficient solutions, eco-friendly options, or simpler tools with more delicate procedures required.

Continuing education is often required to maintain your certification, with ongoing learning opportunities available through professional associations like HSPA and CBSPD.

These can include webinars, workshops, and additional certification programs that help you stay at the top of your field.

Step 8 Consider Advanced Roles

As you gain experience, you might want to explore advanced roles in sterile processing, such as lead technician, supervisor, or educator positions.

Additional certifications, such as the Certified Instrument Specialist (CIS) or the Certified Healthcare Leader (CHL), can open doors to these opportunities and increase your earning potential.

Education

To become a sterile processing technician, education begins with earning a high school diploma or GED.

In high school, students should focus on foundational subjects like biology, chemistry, and mathematics, as these provide a basic understanding of the sciences and analytical skills that are useful in this field.

Courses in health sciences, if available, can also offer early exposure to medical terminology and concepts relevant to sterile processing.

Knowledge of computer programs, software, PCs, and Macs is important as you’ll be using high-tech programs and equipment to tabulate your tasks.

After high school, aspiring sterile processing technicians typically pursue further education through vocational schools, community colleges, or specialized training programs.

These programs, often lasting from a few months to a year, provide targeted instruction in sterilization procedures, infection control, microbiology, medical terminology, and the use of sterilization equipment.

Sterile processing classes can also be taken as part of an associate’s or bachelor’s degree in a healthcare niche.

The curriculum combines classroom learning with practical, hands-on training in a clinical setting, allowing students to learn and practice cleaning, sterilization, and management of medical instruments effectively.

Classes can be held on-site, remotely, or hybrid.

Video About The Career

Licensing & Certification

Most sterile processing technician programs are designed to receive certification, which can also come with a new title to put on your resume – CSPDT (Certified Sterile Processing and Distribution Technician).

Don’t let the lack of a certification requirement, if applicable, deter you from the immense benefits of obtaining one.

Holding certification can significantly improve job prospects, earning potential, and opportunities for advancement within the sterile processing field.

Certain requirements must be met before you can take a certification course, ranging from full-time work in sterile processing for at least a year, completion of an approved training course with at least a grade of 70, or a service sales job related to the sterile processing field for at least a year.

The Certification and the Licensing Process

The Certified Registered Central Service Technician (CRCST), offered by the Healthcare Sterile Processing Association (HSPA), requires passing an exam that tests knowledge acquired during the training program and may also necessitate completing a specified number of hands-on hours in a sterile processing environment.

In general, that number of hours is 400 within the previous five years.

That’s 50 days in five years.

Ongoing education is essential in this field, as it ensures that sterile processing technicians stay updated on the latest sterilization techniques, technologies, and safety protocols.

The most recognized certification is the Certified Registered Central Service Technician (CRCST), offered by the Healthcare Sterile Processing Association (HSPA).

To earn the CRCST certification, candidates must complete a minimum of 400 hours of hands-on experience in a sterile processing department and pass a comprehensive exam covering decontamination, sterilization, and instrument handling.

Another widely recognized certification is the Certified Sterile Processing and Distribution Technician (CSPDT), provided by the Certification Board for Sterile Processing and Distribution (CBSPD).

Similar to the CRCST, this certification involves passing an exam that tests the candidate’s knowledge of sterilization procedures, safety standards, and best practices.

Both certifications require ongoing education to maintain credentials, typically through earning continuing education units (CEUs) from approved courses, workshops, or professional development activities.

Continuing education units (CEUs) are often required to maintain certification, which can be obtained through workshops, webinars, or advanced courses offered by professional organizations.

It’s important to note that a new certification can be earned every five years.

This commitment to lifelong learning helps sterile processing technicians remain competent and compliant with industry standards, ultimately contributing to improved patient safety and quality of care.

Vaccinations

Expect any certificate program, diploma program, or job to require certain vaccinations.

This could include Hepatitis B, Influenza, Pneumonia, Measles, Mumps, and Rubella.

Each state will have exemption considerations for religious, medical, or philosophical reasons.

Additional Certification

Many states have programs that require the American Heart Association Basic Life Support and CPR training cards before you can enroll or start a job.

Be sure to ask that during your campus or job interview.

Average Training Program Duration: 0-6 Months

Popular Programs

Job Outlook

The future demand for sterile processing technicians is strong, with an expected 5% increase through 2033.

That’s an additional 9,500 annual projected jobs opening up.

As surgery and medical treatments increase, so will the demand for skilled sterile techs, as the two go hand in hand.

Plus, considering the expansive field of surgical treatments, from general surgery, emergency surgery, plastic surgery, dental surgery, orthopedic surgeons – the list goes on.

Not only can you work in a field that protects the safety of patients, you can focus on an area of medicine that is important to you.

Another benefit is that every community, from big cities to small towns, will have hospitals, healthcare providers, and surgical centers.

There’s job security knowing that if you need to make a move, you will have places to apply for jobs immediately.

Plus, being a travel tech can also be a more lucrative path once you’ve gained certification and pre-designated experience.

Employment Growth Projection: 5%

2023

2033

That's a higher than average projected growth of 9,500

Should You Become a Sterile Processing Technician?

Overall Satisfaction: Medium

There are numerous subreddits focused on the tasks of a sterile processing technician and stories from real-life workers who either love, loathe, or simply tolerate the job.

Overall, it’s important to work at a place that values teamwork and gives you a clear picture of the workload and stress scenario.

Working in an emergency room will bring high-stress levels but the potential for high satisfaction.

Working at a routine surgical center could be isolating and lonely if you are not around a lot of other colleagues.

Average Salary: High

The minimal education requirements will offset the high student loan payments of more lucrative medical jobs, but the salary doesn’t have much room to improve beyond the high end of salary studies.

Outpatient care centers have the highest annual mean wage, at $54,890, as of May 2023.

General medical hospitals and surgical centers have a mean salary of $47,940.

Dental offices have the lowest mean average at $36,020.

Working at specialty hospitals, such as psychiatric centers or substance abuse centers, earns among the highest salaries for medical equipment preparers, at $55,300.

Job Growth Outlook: High

Sterile processing technicians fall into a Bureau of Labor Statistics category known as medical equipment preparers (31-9093).

As noted above, the outlook projects a growth of 6% between now and 2023.

That number could increase with the number of surgical centers and hospitals.

Plus, with the Baby Boomers reaching Medicare age, there’s also an expectation of a higher demand for healthcare throughout the next decade.

Education Duration: 1-3 Years

The education required to become a sterile processing technician is relatively short compared to many healthcare roles.

Most training programs offered by community colleges, vocational schools, or online providers can be completed in about four to six months.

These programs combine classroom learning with clinical training.

For those pursuing certification, such as the CRCST, additional hours of on-the-job experience are required, which can typically be completed alongside or shortly after the formal training.

Overall, the entire process often takes less than a year to enter the workforce with post-high school education or certification.

However, it’s possible to enter the sterling processing technician workforce right out of high school, albeit at a likely lower pay rate due to the learning curve.

Personal Skills Needed

Sterile processing technicians need mental, emotional, and psychological traits to succeed.

- Strong attention to detail

- Good manual dexterity and hand-eye coordination

- Impeccable organizational skills

- Effective communication skills paired with the ability to work with a variety of personalities

- Problem-solving abilities

- Comfort working in a fast-paced, high-pressure environment.

- Dedication to maintaining high standards

- Ability to work various hours or times of day, including weekends and overnights

Frequently Asked Questions

Q. How long do you have to go to school to become a Sterile Processing Technician?

Becoming a sterile processing technician typically lasts about four to six months of post-high-school training, but there are opportunities right out of high school to start working.

Higher education, available at community colleges or vocational schools, includes both classroom instruction and hands-on clinical experience.

Some individuals may also pursue certification, which requires additional practical hours, but the overall process usually takes less than a year.

Q. How much money does a Sterile Processing Technician make a year?

According to the Bureau of Labor Statistics, the average salary for a sterile processing technician nationwide is $47,410 per year or $22.79 per hour.

According to Indeed, the average base salary for sterile processing technicians is $34.03 per hour, with a low of $25.70 and a high of $45.06.

According to ZipRecruiter, the average salary for a sterile processing technician is $57,186 per year, with the 75th percentile at $69,000 and the 90th percentile at $81,000.

Q. What kind of education do you need to be a Sterile Processing Technician?

A strong high school grasp of STEM classes, especially math, chemistry, and science, can get your foot in the door.

However, getting an associate’s degree or taking a certification course in sterile processing technology is the gold standard for finding a quality job with a liveable wage.

Q. Are Sterile Processing Technicians in high demand?

As long as surgeries and procedures are performed in healthcare, there will be a demand for sterile processing technicians.

Looking ahead through 2033, there’s anywhere from a 5% to 8% increase, which is at or slightly above average.

That percentage will rise with the demand for surgical procedures.

Surgeons and physicians are expected to increase by 4% over the next decade.

Q. What skills do you need to have to be a Sterile Processing Technician?

Skills for being a good sterile processing technician include a strong grasp of science, math, and chemistry, a likable personality, and an ability to consistently perform excellently, even in high-pressure situations.

Organizational skills and attention to detail are equally important as having a steady hand and good eyesight when looking at items up close.

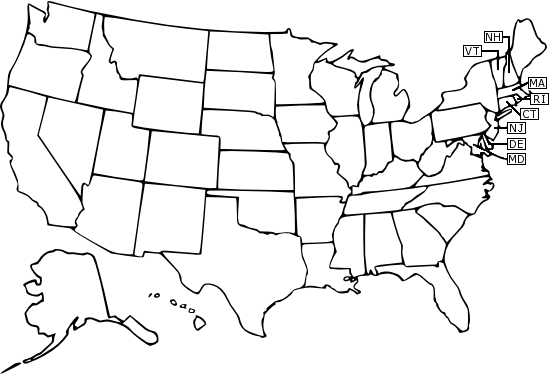

Sterile Processing Technician Classes by State

Sterile Processing Technician Classes by State

- Alabama

- Alaska

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- Florida

- Georgia

- Hawaii

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Kentucky

- Louisiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Minnesota

- Mississippi

- Missouri

- Montana

- Nebraska

- Nevada

- New Hampshire

- New Jersey

- New Mexico

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virginia

- Washington

- West Virginia

- Wisconsin

- Wyoming

This page is also available in Spanish.